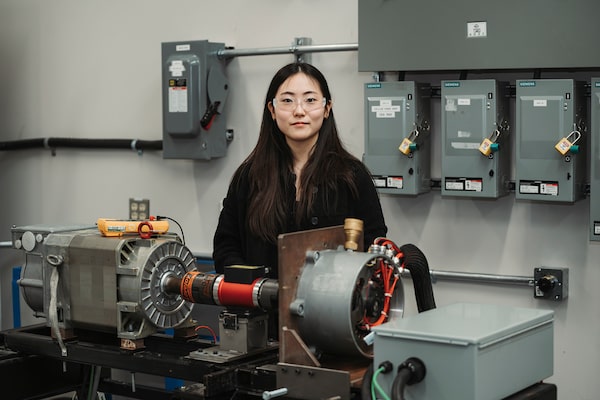

Alice Seo is a third-year electrical engineering student at University of Windsor, who completed an on-site co-op placement with Toronto-based D&V Electronics, where she learned trouble-shooting methods from “hands-on experience. I felt it was really valuable.”SUPPLIED

When Alice Seo was a teenager, she wanted to be a dentist. Instead, she’s joined the electric-vehicle revolution.

Ms. Seo, a third-year electrical engineering student at the University of Windsor, is helping to build the EVs of the future in its world-class CHARGE Lab.

The CHARGE (Centre for Hybrid Automotive Research and Green Energy) Lab is the university’s research facility dedicated to designing and testing innovative EV components, in partnership with original equipment manufacturers and Tier 1 suppliers for the auto industry. It’s also a training ground for students like Ms. Seo, building a bridge between academia and real-world experience.

Ms. Seo says her curiosity switched from dentistry to electric circuitry when her Windsor high school pivoted to remote learning during the COVID-19 pandemic.

“We couldn’t do a lot of experiments in chemistry and biology, so I started to focus on physics,” she recalls. “I became really interested in circuits.”

Narayan Kar, founder of University of Windsor’s CHARGE Lab, a research facility dedicated to designing and testing innovative EV components, which focuses on hybrid and electric-vehicle technology.SUPPLIED

During her first year at UWindsor, she was accepted into the Outstanding Scholars program and approached CHARGE Lab’s founder, Prof. Narayan Kar, about joining his lab.

Apart from assisting in CHARGE Lab’s research and development, Ms. Seo has also spent a couple of semesters in a co-op program, working with Toronto-based D&V Electronics, which designs and manufacturers testing systems for electric and hybrid vehicles. After her first four-month placement, D&V was reluctant to let her go, so she spent a second semester working remotely for the company while continuing her studies.

Ms. Seo says her stint at D&V as a controls engineer introduced her to trouble-shooting methods she wouldn’t have learned in class. “They were the sort of things where you have to be on-site and learn from hands-on experience,” she says. “I felt it was really valuable.”

CHARGE Lab doesn’t just send students into the industry but also brings the industry to the campus. The lab, located in UWindsor’s Ed Lumley Centre for Engineering Innovation, teams with major players, such as the Ford Motor Co. and Magna International Inc., who have engineers and offices on-site. They also spark – and fund – much of the research.

“What we’re doing here isn’t blue-sky research in nature,” says Prof. Kar, who holds a Tier 1 Canada Research Chair in Electrified Vehicles. “We identify the real-world problems in electric-vehicle technology and work with industry to solve them.”

The lab’s research focuses specifically on EV powertrains and controls and in 2022 completed a $4-million upgrade to add state-of-the-art testing facilities.

Magna, a global mobility technology company, has a relationship with CHARGE Lab dating back to 2017. The company has worked with the centre on research and development projects, provided equipment, published patents and co-authored papers with professors and students for top journals.

It plans to have an even bigger involvement this year when it opens the Magna-University of Windsor Electric Mobility Technology Centre as part of the lab.

Lakshmi Varaha Iyer, a senior manager in Magna’s advanced powertrain and chassis division, says it’s a perfect arrangement. “Having our engineers based at the university gives us the flexibility to approach a professor and say, ‘Can you help us solve this problem?’”

Prof. Iyer says the collaboration with Magna, which chose Windsor for its first North American innovation hub, works both ways. “Sometimes a professor calls us and says, ‘We have some new technology, do you want to take a look at it?’”

“Having our engineers based at the university gives us the flexibility to approach a professor and say, ‘Can you help us solve this problem?’

— Lakshmi Varaha Iyer, senior manager, Magna International Inc.

There are plenty of challenges still to be tackled in making EVs more efficient and affordable as Canada moves towards 2035 – the year that, by federal mandate, all new passenger vehicles off the assembly line must be battery-electric or plug-in hybrid electric vehicles.

When Prof. Kar launched CHARGE Lab, a few years after joining UWindsor in 2003, it was devoted to hybrid vehicles. Today, he says, “our focus is on hybrid and electric-vehicle technology.”

The lab currently includes 35 students, primarily at the master’s and PhD level, along with three postdoctoral researchers. It also collaborates across disciplines with UWindsor professors from materials engineering, computer science and chemistry, among others. Nationally, it has joined forces with other universities on projects, including the University of Toronto and Montreal’s Concordia University. “We are also developing collaborations with multiple universities in Italy, Mexico and India,” Prof. Kar adds.

Sustainability is a key motivator in CHARGE Lab’s research. Prof. Kar says that the components of a zero-emissions electric vehicle also need to be green. To that end, the lab is immersed in a $4.3-million development program, funded both by government and industry, to create an alternative to the standard permanent-magnet motor.

“The materials used for those motors, from mining to processing to magnet development, are not very environmentally friendly,” he says. Instead, the university and its partners – Ford, D&V and Nemak Corp. – are developing a magnet-less induction motor that will be equally powerful and improved sustainability.

Along with creating technological innovations, CHARGE Lab is also providing another major need – a highly skilled workforce for the new EV industry.

“The [people] doing the primary work here are the students,” Prof. Kar says. “And the best way of teaching them is by having them work on industry projects with industry engineers in the lab. It results in the students not only being trained in a meaningful and effective way, but also the industry is training their future employees.”

Indeed, Prof. Iyer notes that, after they graduated, seven former students who worked on a collaborative project with Magna were hired by his company.

Ms. Seo is among the students keen to contribute to the industry. “I’m hoping to do my master’s in the CHARGE Lab,” she says. “After that I’ll be applying to get a job in an EV-related field.”

UWindsor research aims to combat hackers, decrease risk of EV theft

The alarming rise in auto thefts in Canada over the last few years has thrown a harsh spotlight on vehicle cybersecurity. Many of today’s “smart” cars are stolen by hacking into their keyless locks and push-to-start ignitions, prompting the federal government to demand that automakers reveal their measures to prevent cyberattacks.

Mitra Mirhassani, a professor in the University of Windsor’s Department of Electric and Computer Engineering and an expert in cybersecurity, says that attention is overdue. But she adds that auto thefts are just the tip of the iceberg when it comes to vehicle vulnerabilities.

“There are more problematic issues,” she says, ranging from data theft “to loss of life.”

The North American auto industry got its first taste of those dangers in 2015, when a pair of hackers showed how they could gain remote access to a Jeep Cherokee’s operating systems, wresting control of its steering, brakes and accelerator from the driver. It forced the Jeep’s manufacturer, Fiat Chrysler, to recall 1.4-million vehicles.

At the time, Prof. Mirhassani was doing research into security issues with AI hardware and realized many of those digital components were being used in cars. “I found no one in the automotive sector was talking about cybersecurity as part of their design criteria,” she says. “It was a real issue that needed to be addressed.”

In 2021, she and fellow UWindsor professor Ikjot Saini launched the SHIELD Automotive Cybersecurity Centre of Excellence, Canada’s first organization devoted to combatting cyber threats to the transportation marketplace.

The centre conducts research into the many risks of computerized vehicles. It also provides training for much-needed cybersecurity professionals and is building a growing list of industry partnerships. Among its close collaborators is Block Harbor, a Detroit-based company that provides automotive cybersecurity solutions.

Block Harbor is a team of automotive cybersecurity experts united under the goal of building great solutions to keep mobility safe. They have nearly a decade of experience in fortifying vehicles against cyber threats under their belt and are developing mitigation test suits to the community of vehicle cybersecurity auditors, automakers and suppliers.

“Mitra and her team are early pioneers in this area,” says Block Harbor founder and chief executive officer Brandon Barry. “We’re happy to support their initiatives, where we develop technology that can then be used by their organization.”

Mr. Barry says that cars are becoming like an iPhone on wheels, with increased connectivity and autonomy, and each new feature adds another potential “attack surface.” It will only get worse as the auto industry transitions to electric vehicles. “EV chargers that plug into cars are a huge risk point,” he says.

Along with the vehicle itself, the AI components that control its communications and navigational systems are also vulnerable. Prof. Mirhassani says one area of SHIELD research involves fraudulent software updates.

“The car owner might receive a notice that an update is required, but it could actually be a malicious actor trying to get into the car,” she explains. “With technology provided by Block Harbor, we’ve been looking at how you can verify whether a software patch is real or fake.”

Block Harbor is also assisting in SHIELD’s educational efforts, helping to shape courses for UWindsor students interested in entering a nascent field.

“The biggest automotive cybersecurity threat in Canada is the lack of talent,” Prof. Mirhassani says. “Our primary mandate is to create a skilled workforce that can deal with these issues.”

Advertising feature produced by Globe Content Studio with University of Windsor. The Globe’s editorial department was not involved.